The Definitive Guide to Wedge Barriers

Wiki Article

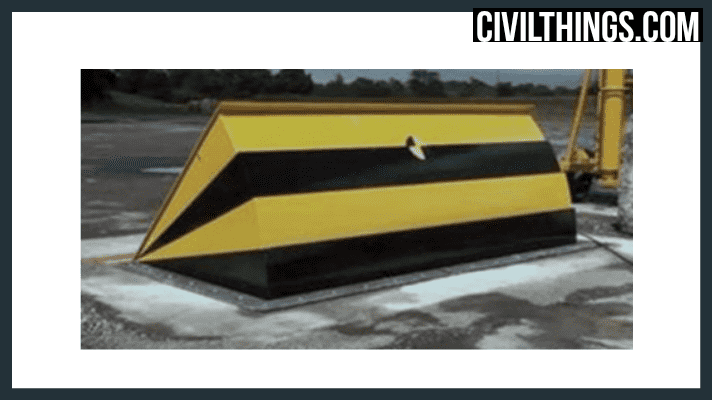

Wedge Barriers - An Overview

Table of ContentsThe Of Wedge BarriersExcitement About Wedge Barriers

Facts About Wedge Barriers Uncovered

g., springtime support 65 )might be repaired to completion of the spring rod 58 to allow compression of the springtimes 60. As the springs 60 are pressed between the springtime sustains 62, the spring setting up 54 generates a pressure acting upon the webcam paired to the springtime pole 58 in a direction 66. As an example, the remaining pressure put on the cam to deploy the wedge plate 16 might be supplied by an electromechanical actuator 84 or various other actuator. The spring assembly 54 and the actuator 84(e. g., electromechanical actuator)may run with each other to translate the webcam and lift the wedge plate 16.

As mentioned above, the springtime assembly 54 puts in a consistent pressure on the camera, while the electromechanical actuator may be regulated to apply a variable pressure on the web cam, thereby enabling the lifting and lowering( i. e., deploying and pulling back )of the wedge plate 16. In specific embodiments, the consistent pressure used by the springtime assembly 54 might be flexible. g., electromechanical actuator) is impaired. As will be valued, the springtime setting up 54 might be covered and secured from particles or other aspects by a cover plate(e. g., cover plate 68 displayed in FIG. 4) that may be significantly flush with the elevated surface 38 of the foundation 14. As discussed above, in the deployed position, the wedge plate 16 offers to block accessibility or travel past the obstacle 10. The barrier 10(e. g., the wedge plate 16 )might block wikipedia reference pedestrians or automobiles from accessing a residential or commercial property or pathway. As talked about over, the obstacle 10 is connected to the support 30 safeguarded within the structure 14,

front brackets 71. Because of this, the affiliation settings up 72 may pivot and rotate to allow the collapse and extension of the link assemblies 72 during retraction and implementation of the bather 10. The linkage assemblies 72 reason movement of the wedge plate 16 to be limited. For example, if a vehicle is traveling towards the deployed wedge plate 16(e. For instance, in one scenario, the safety legs 86 might be expanded duringupkeep of the barrier 10. When the security legs 86 are deployed, the safety and security legs 86 sustain the weight of the wedge plate 16 versus the surface 12. Consequently, the lifting mechanism 50 may be deactivated, serviced, removed, replaced, and so forth. FIG. 5 is partial perspective sight of a personification of the surface-mounted wedge-style barrier 10, illustrating the webcam 80 and the cam surface areas 82 of the training mechanism 50. Specifically, 2 webcam surfaces 82, a fantastic read which are described as lower camera surface areas 83, are placed below the web cam 80. The lower webcam surfaces 83 might be taken care of to the surface 12 (e. For example, the reduced webcam surface areas 83 and the installing plate 85 may develop a single item that is secured to the support 30 by bolts or various other mechanical fasteners. In addition, 2 cam surface areas 82, which are referred to as top cam surface areas 87, are positioned above the webcam 80 and paired to (e. In other embodiments, stepping in layers or plates may be positioned in between the surface 12 and the reduced cam surface areas 83 and/or the wedge plate 16 and the top webcam surface areas 87 As mentioned over, the cam 80 equates along the web cam surfaces 82 when the wedge plate 16 is lifted from the withdrawed setting to the released setting. In addition, as mentioned above, the springtime assembly 54 (see FIG. 3 )may give a force acting upon the cam 80 in the direction 102 using spring pole 58, which might lower the force the electromechanical actuator 84 is check my source required to relate to the web cam 80 in order to actuate and lift the wedge plate 16. 1 )to the released setting(see FIG. 4). As shown, the web cam 80 includes track wheels 104(e. g., rollers), which call and equate along the camera surface areas 82 during operation.

Report this wiki page